Early in our workshop week (first week of November) an area of the plant was tasked with selecting a focus operation upon which two skills were to be practiced. The practicing team included the Area Lead, Supervisor, Site CI Lead, Training Coordinator and CI Engineer. The line was running so there was ready access to the people doing the work, the ones who know the work best. The 50lb (granular product) bag sealer was chosen as there’d been periodic issues with bag seal quality for some time.

The first day of the week focussed on what effective workplace training can look like when built on a solid foundation of work standards. Training practice was rigorous.

Day two started with an overview of the concepts of visual thinking communicated via a 2021 webinar with Dr Gwen Galsworth. Four key concepts were then introduced:

- The cycle of struggle and firefighting.

- Visual devices help learning.

- The role of visual devices.

- Power levels of visual devices.

A Plan Do Check Adjust based ‘make normal easy to see’ cycle was practiced on our mini simulation before heading into the plant.

Participants were then provided reference pocket cards (pictured below) and the three groups headed into the plant to combine workplace experimenting with the ‘normal easy to see’ cycle.

Our bag closing group quickly determined they’d focus on feeding of the bag into the bag sealer. Even very experienced workers struggled with this task from time to time. Broadly, here’s their iterations over the next three days. (The three days were intermingled with other activities.)

Zack, Andy and Stephen measuring up a guide to help the operator feed the bag into the sealer straight.

Click here to view Zack testing iteration 1; Andy is in the background. Provided the bag top stays in the green area, the bag seal is ‘normal’ (good) as per the output work standard. If the bag drops into the red area as it’s being fed in, an ‘abnormal’ seal will result. This was proven in the first design experiment. Note: The red/green background is pencil on paper and the feed in guide is cardboard and duct tape!

Click here to view Zack testing iteration 2; Dirk (CI Director) is in the background with Juvenico, an operator. Note: The red/green background is now industrial tape and goes the full length of the bag feed area.

Click here to view Zack testing iteration 3; Juan (QA, California plant) and Matt (Zacks manager) are in the background. Note: The cardboard and duct tape feed in guide is now an aluminium device the group made. It is now at the prototype stage ready to go to engineering to be ‘properly fabricated’.

Throughout development, as the line was running, highly valued operator feedback from line experts happened naturally. Zack used iteration 3 to train night shift on the Wednesday evening. ‘Keep in green’ was a visual key point.

Here’s the finished fabricated system mounted on the bag sealer.

The outcome of combining workplace experimenting and visual thinking was the cycle of struggle and firefighting was weakened. Perhaps a less measurable outcome, but more important, was engagement rose due to rapid cycling of frontline ideas. To achieve and reliably sustain improvement results, your people need to design THEIR OWN experiments with THEIR OWN ideas, NOT YOURS. It is their machines, their workplace, and their environment.

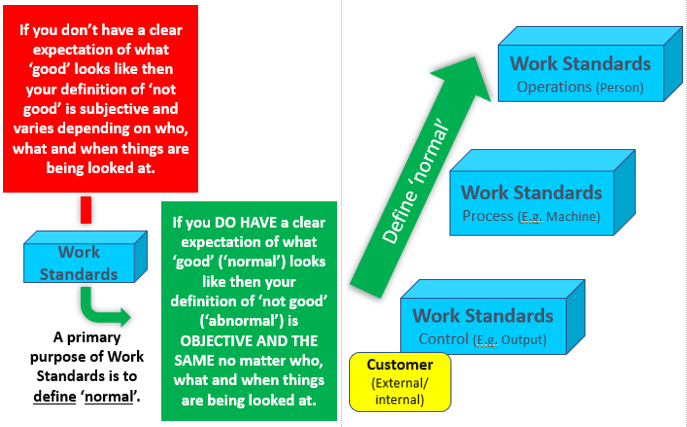

Watch the related webinar here. Below is the image of the ‘three types of work standards’ that Ann referred to.